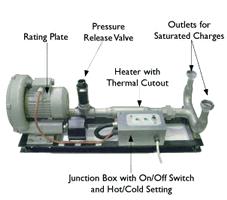

Hawke have designed a new, highly efficient, specialist drying unit that can be used on all HB products. The unit comprises of : A (240 volt or 110 volt) Blower Motor complete withthermal protection, 1/2 Kw Heater element, Pressure release valve and air filter, Stainless Steel two way connecting pipework and manifold withadaptors accepting up to two breather charges, Substantial mild steel black enamel coated framework.

- Transformer Breather Dryer Unit will dry out and recharge saturated charges. This exercise can be carried out 3 times prolonging the working life of each charge.

General Information

The Breather Dryer Unit (referred to as “dryer unit”) is designed to be mounted or placed

onto a level base/floor in a horizontal position. It consists of a blower motor which has a filtered input. The blower is connected through pipework which contains a factory set pressure relief valve to a temperature limited tube heater which in turn is connected to a pipework branch system which contains threaded couplers and adaptors to accept the different sizes of breather charges. All of the above are mounted onto a steel framework which also contains the unit’s control box. The outside of the control box consists of a three positioned selector switch & two green indicator lamps. The control box allows the unit to be switched “Off”, switched to a non-heated position where only the blower operates or to a position in which both the heater and blower operate together.

It is possible to dry either a single breather charge or two charges simultaneously. The charges may also be different sizes. Please use the supplied adaptors to change the threads to the appropriate size for the breather charge.

The maximum temperature possible on the exposed pipework is limited to prevent it exceeding 40°C.

Power Requirements

The dryer unit control box contains the ratings label.

The dryer unit can be supplied with two different supply options. In both cases the units MUST be securely connected to the supply protective earth conductor:-

Option 1

For use on 230V AC single phase 50Hz supplies. (Maximum current 8 Amps).

Product Code:- HBDU240V.

Option 2

For use on 110-120V AC single 60Hz supplies. (Maximum current 15 Amps).

Product Code:- HBDU110V.

The heater is rated at 500 watts in both options 1 and 2.

The direction of rotation of the blower motor is clearly shown on the motor casing and should be checked on commissioning and after any maintenance work to ensure that the rotation is correct.

The power to the dryer unit MUST be supplied through a residual current device (RCD) which has a 30mA trip protection level to protect operators. The circuit should also be close circuit protected to prevent excessive circuit currents under fault conditions. The integral cable supplying the breather dryer unit should be mechanically protected if installed in an area which could render it subject to mechanical damage.

Health & Safety/Handling Safely

1. Caution:- The breather charges, in certain cases, weigh in excess of 20Kg. Care should be taken when handling these heavy charges, it is recommended that two people lift the charge together.

2. The dryer unit should not be connected to the supply until all protective bungs are removed and the unit is safely positioned on a stable foundation.

3. The dryer must be isolated from the mains supply prior to any removal of covers for maintenance purposes.

4. The dryer unit is designed for use in areas inside buildings which are dry and clean. They must NOT be operated in areas which contain or could contain potentially explosive mixtures of gas and air or dust and air mixtures.

5. The input to the filter and the output at the branched section of the pipework MUST not be fully closed off. Care should be taken to monitor the operation of the unit to ensure that inflammable materials (i.e. paper, wood, cloth etc.) do not cover the blower input, the fan impeller cover or the heated blower tubing.

6. Care should be taken to ensure foreign bodies do not enter the pipework section.

7. The pressure relief valve is preset and should not be altered/adjusted.

8. The unit weighs approximately 40Kg and special precautions should be observed when attempting to lift/move the unit. Soft slings should be used which are suitable for the weight. They should be placed securely around the steel framework, before being connected to any lifting equipment (i.e. fork lift truck). Under no circumstances should any person try to move the dryer unit on their own without suitable mechanical handling equipment.

Method of Operation

1. Before commencing operation, care should be taken to lubricate the male breather charge thread and the dryer unit female threads with aluminium anti-seize paste.

2. Remove one of the adaptors from the branched pipework and attempt to screw the adaptor onto the male thread on the underside of the breather charge. The adaptor shoulder should be positioned close to the breather charge shoulder.

3. If the adaptor fits onto the thread, screw the adaptor/breather charge onto the coupling on the branched pipework until tight.

NOTE:- It is recommended that two people are used to fix any charges weighing over 20Kg onto the pipework.

4. If the adaptor does not fit onto the breather charge, then screw the charge directly onto the pipework until tight.

NOTE:- It is recommended that two people are used to fix any charges weighing over 20Kg onto the pipework.

5. This can be repeated on the second branch of the pipework.

If only one charge is to be dried, place the stopping bung (with a hole inserted) into the unused branch coupler.

6. Ensuring the control box three positioned selector switch is in the “off” position, apply power to the dryer unit.

7. Switch the selector switch to the fan and heater position. The drying sequence will commence and the breather charge will gradually change colour during the drying process until the desiccant is back to the original deep orange colour indicated on the label. (This should take about 3 hours depending upon the size of the breather charge).

Please be aware that some of the dryer unit pipework will get hot during the drying process.

When the drying process is complete, the selector switch should be turned to the “Off” position and the charge should be allowed to cool for 20 minutes before removing from the dryer. If the breather charge is not to be placed directly into service, the ends will need to be closed off to prevent moisture entering the charge.

Maintenance/Spares

The blower input filter should be replaced every twelve months. Contact Cable Systems Ltd for details.

Spares Listing

If spare parts are required, please contact Cable Systems Ltd. sales@cablesystems.co.uk

Typical Spares

1. Blower Motor

2. Filter

3. Pressure Relief Valve

4. 500 Watt Heater

5. Adaptors

6. Controller