How Unistrut works: What it is and how it gets put together.

Unistrut is an incredibly versatile framing system for completing projects with ease. If you are new to the Unistrut framing system and need a few pointers on how Unistrut works, we have just the post for you.

What is Unistrut Metal Framing?

We often compare Unistrut to the Meccano sets we played with as kids. The core of the Unistrut framing system—the metal framing channel—allows infinite positioning of fittings along the entire piece of strut without welding or drilling. Fifteen channel sizes and hundreds of fittings offer solutions to a virtually endless variety of projects. Because all of the connections are made using bolts and channel nuts, Unistrut is also reusable. Infinite adjustability and reusability makes Unistrut an attractive option for many different industries and applications, including:

- Storage Racks and Shelves

- Pipe and Conduit Supports

- Ceiling Support Grids

- Equipment, Tool, and Sign Supports

- Ceiling Support Grids

- Cable Tray Supports

- Rooftop Pipe Support Systems

- Material Handling Systems

- Platforms, Tables, and Risers

- Rooftop Walkways

- Solar Panel Support Systems

- Medical Equipment Supports

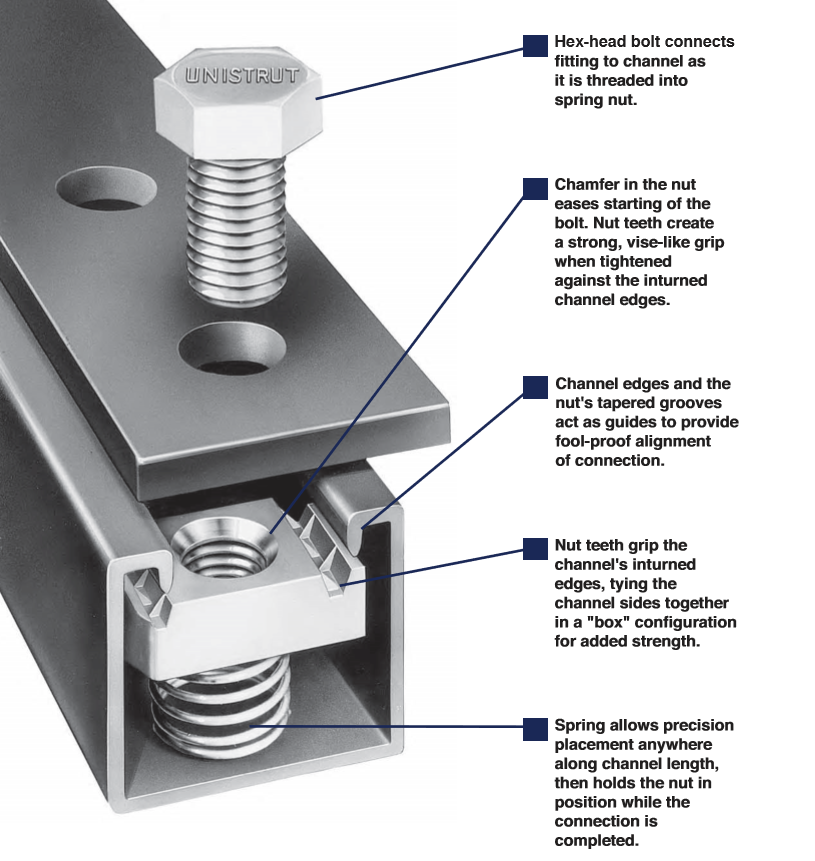

So how exactly does this process work? The image below shows exactly how Unistrut can provide vice-like connections without the need for welding, drilling, or special tools.

Please note that the image above shows a channel nut with spring. Unistrut channel nuts are also available without springs and work in a similar manner. The only difference between the two is that the spring holds the channel nut in a more precise location, which is useful for applications when you are working with channel that is suspended overhead.

How to make Unistrut Connections in five easy steps

Take your channel and insert the nut anywhere along the continuous slotted channel. The rounded nut ends make it easy to insert into the channel. The nut pictured features a spring, but any Unistrut nut will work.

Turn the nut 90 degrees clockwise and align the grooves in the nut with the inturned edges of the channel.

Place a fitting over the nut and insert the bolt through the fitting and into the nut. This will hold the nut and fitting in place.

You can now bolt additional channel sections to the attached fitting by following steps 1-3.

If you don’t need to make any adjustments, tighten the net with a wrench. This locks the serrated teeth of the nut into the inturned edges of the nuts and creates a strong, vice-like connection.

Design the structures you need with Unistrut

Unistrut is the building material of choice for many professionals because it’s 100 percent adjustable, reusable, and requires no welding, drilling, or special tools. If you have a hand wrench, you can make a Unistrut connection. From there, Unistrut gives you the means to build adjustable structures based on your needs; all it takes is a little planning and the right materials.

If you are ready to get starting building with Unistrut, download the Unistrut Catalogue to learn more about the different types of channel, fittings, channel nuts, and hardware we have available, or order the Unistrut products you need online.

If you have any questions or need some assistance with your applications, contact us today for more information. We can help you find the materials you need or provide you with several beneficial services that can help you with your project:

- Application consultation

- Design engineering

- Engineered drawings

- Cutting, kitting, and bundling

- Fabrication assembly