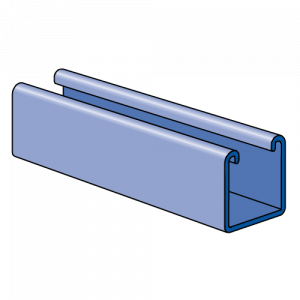

Unistrut is a convenient metal framing system that dates back to the 1930s and is hugely popular in the present day for its fast and flexible construction and reconfiguration.

Temporary and permanent structures alike can be built using Unistrut, with no welding required – a significant advantage in hazardous zones where sparks from welding gear would be unacceptable.

You can think of Unistrut as a kind of grown-up Meccano for industrial environments, and in fact Unistrut once released a kit for children to play with, which has become a collector’s item.

Over the decades, Unistrut has evolved to include a comprehensive range of supports, including inserts to embed into concrete, and suspended cable trays for ceiling-level power and data wires.

The incredible versatility of Unistrut has led to it being used in many different types of environment:

- Catwalks and mezzanines

- Clean rooms

- Laboratories

- ‘Living’ walls

- Pharmaceutical

- Solar racking

In addition to cable trays, Unistrut can be used to construct quick and sturdy supports for equipment ranging from medical devices, to mechanical rooftop supports, to ceiling grids and signage.