Self-regulating heat cables, also known as heat trace cables, work to prevent pipes and cables from freezing in extremely cold conditions, including in hazardous areas when certified and rated for such use.

Using self-regulated heat cables means that this protection is continual, as the cable will automatically adjust to any changes in the ambient temperature.

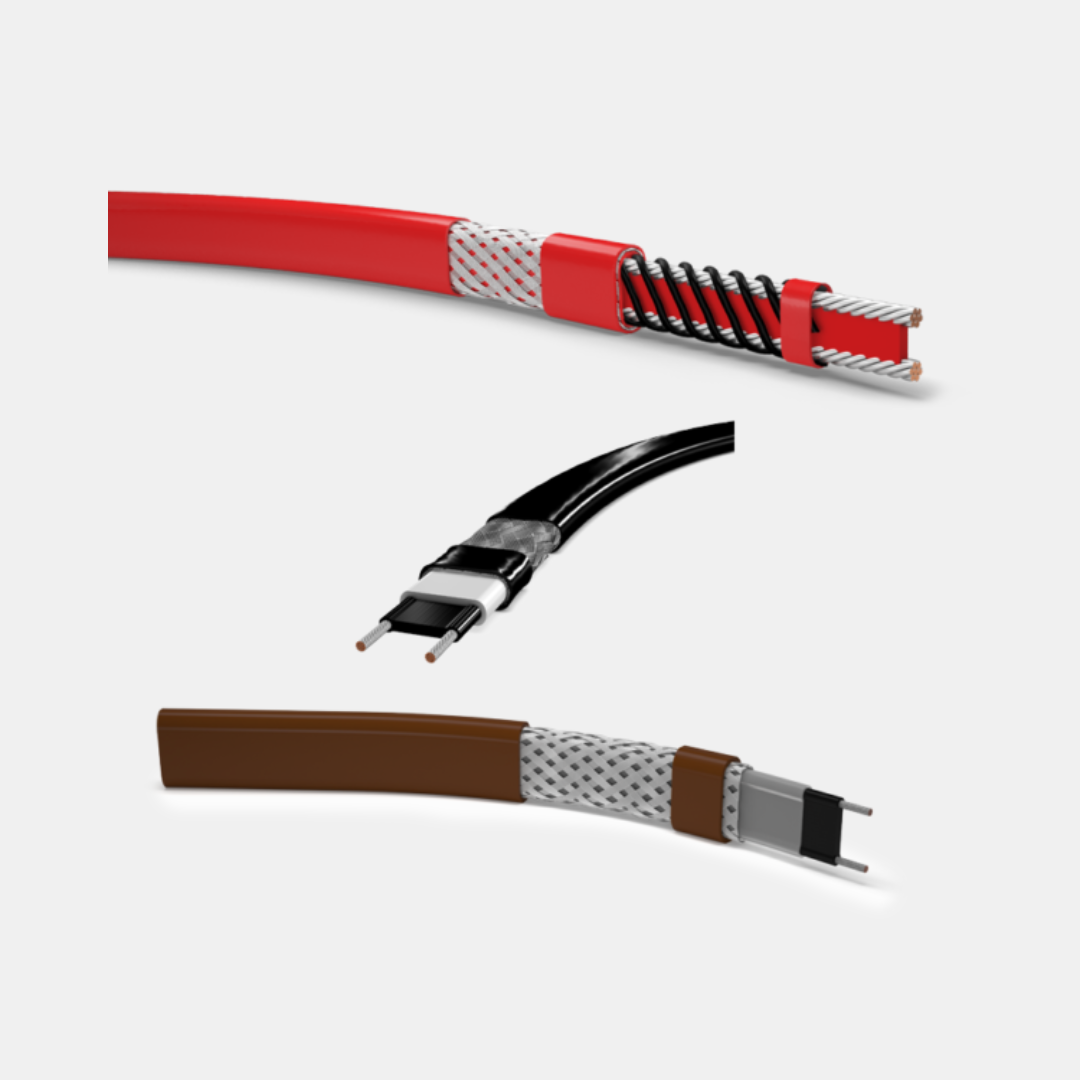

This is thanks to the unique construction of the cable, its parallel conductors and its conductive polymer heating core, which we’ll look at in more detail below.

What is self-regulating heating?

Self-regulating heating means that as ambient conditions surrounding the cable change, it responds by heating up, to prevent electrical freezing or frozen pipes.

This can remove the need for external heaters in hazardous areas, keeping cables safe and mitigating the risk of ignition or explosion in the presence of dust, gases and vapours.

As with all hazardous area products, self-regulating heat trace cables can be rated for different zones, including Zone 1/2 and Zone 21/22.

Self-regulating heating cables often have multiple stated operating temperatures, such as:

- Maximum continuous exposure temperature

- Maximum intermittent exposure temperature

- Maximum exposure equivalent in steam psi

The cables can also be protected against corrosion and other damage, using a fluoropolymer exterior jacket that helps to resist chemical damage and mechanical deformation.

When do you need self-regulating heat cables?

Self-regulating trace heat cables can serve a wide range of purposes, including:

- Freeze protection

- Process temperature maintenance

- High-temperature heating

Applications range from on-demand delivery of hot water from taps, to dealing with snow meltwater running off roofs, and everything in between.

You should particularly consider hazardous area-rated heat cables in the presence of flammable or explosive gases and dusts. For more information about the hazardous area rating of any product, download the datasheet or just ask.

How do self-regulating heat cables work?

Raychem self-regulating heat cables work by using a conductive polymer core between two parallel conductors.

When ambient temperatures fall, the core increases its output, heating up to protect the cable, pipe or conduit against freezing.

This can also be used to maintain process temperatures for fluids passing through pipes, so that efficiency and output volume do not drop during cold weather.

Why should you invest in self-regulating heat cables?

Self-regulating heat cables are a proven technology. Raychem alone have supplied over 1.8 billion feet of their heat trace cables to sites in more than 100 countries.

You’ll find even more choice in our Trace Heating department, which includes accessories, thermostats, junction boxes and power connection kits.

For an incredibly affordable price per metre, you protect your pipes, conduits and cables along their full length – and in a wide range of environmental conditions.

Best of all, these cables are self-regulating. Once installed, they should require little to no monitoring and maintenance in order to function correctly – just an occasional condition check to spot any accidental damage.

Find out more

Full technical info and downloadable datasheets are available on our website, including details of the maximum intermittent and continuous exposure temperatures each cable can withstand.

If you’re not sure which is right for your purposes, just ask – we can help you decide based on the type of hazardous area you operate, the gauge of wire you need, and other characteristics of each product.

All of our hazardous area self-regulating heating cables are certified to international standards for the relevant zones, giving you peace of mind that your installation will comply fully with the appropriate safety rules and regulations.